Course Pamphlet | Schedule | Enrollment | Professional Registration

Contents

- 1 Introduction

- 2 Who should attend?

- 3 Course Outline

- 3.1 Identification of Six Sigma Project in the Organization

- 3.2 Structured Approach to collect data and information for your Six Sigma Project

- 3.3 Building the Six Sigma Analytical Tool Kit

- 3.4 Team Dynamics – Working with and through others to get project breakthrough

- 3.5 Sustaining gains and institutionalizing change with your Six Sigma Project

- 4 Certification and Professional Registration

- 5 Course Fee

- 6 Six Sigma Green Belt Time Table

- 7 Six Sigma Green Belt

- 8 Six Sigma Green Belt Entry Requirements :

Course Name: Six Sigma Green Belt

Six Sigma Institute is the only Examination Centre for the Certified Six Sigma Green Belt of the China Association for Quality in Hong Kong.

What is Six Sigma? What is Lean? What is the relationship between them?

Introduction

Six Sigma Green Belts are a vital part of a successful Six Sigma programme. Many organisations begin Six Sigma deployments by training capable employees to become Green Belts. They involve a larger critical mass of people to achieve breakthrough results from their Six Sigma initiatives. The aim of this course is to share our successful knowledge on how to apply the Six Sigma tools in achieving breakthrough improvements in customer satisfaction, cost reduction, process improvement and cycle time reduction.

The Six Sigma Green Belt Program contains of lectures, workshops and project works. Real study cases will be shared.

Who should attend?

- Senior team leaders and managers.

- Quality and process improvement professionals.

- Those interested in becoming Six Sigma professionals.

Course Outline

Identification of Six Sigma Project in the Organization

[DEFINE]

-

- Introduction to SSI’s Green Belt Course

- Overview of Six Sigma and Its Recent Development

- Project Identification and Selection

- Project Charter

- Case Study – PDI Ltd

- Define the Process

- Case Study – SIPOC Chart

- Voice of Customer

Structured Approach to collect data and information for your Six Sigma Project

[MEASURE]

-

- Overview of Measure Phase

- Detail Process Map and Top-Down Chart

- Case Study – Process Map

- Case Study – Top-Down Chart

- In/Output Analysis and C&E Matrix

- Case Study – In-Output Analysis and C&E Matrix

- Measuring and Collecting Data

- Data Sampling Methods

- Measurement System Analysis

- Introduction to SigmaXL

- Basic Statistics

- Baseline Measure

- Baseline Metrics

- Case Study – Discrete Data

Building the Six Sigma Analytical Tool Kit

[ANALYZE]

-

- Overview of Analyze Phase

- Process Analysis

- Identify Root Cause

- Case Study – Graphical Data Analysis

- Testing Relationships

- Regression Analysis

- Chi Square Test

- Confirming Improvement Results

Team Dynamics – Working with and through others to get project breakthrough

[IMPROVE]

-

- Improve Phase Overview

- Generating Ideas for Solutions

- Piloting

- Cost Benefit Analysis

- Case Study – Improve

- Implementing the Solution

Sustaining gains and institutionalizing change with your Six Sigma Project

[CONTROL]

- Control Phase Overview

- Process Risk Management – FMEA

- Control Plan

- Handoff Plan

- SPC for On-going Control

- Case Study – Attribute Control Charts

- Introduction to TOCLSS

- Why Six Sigma Professionals Have Better Career Opportunities

- Overall Review

- Mock Paper

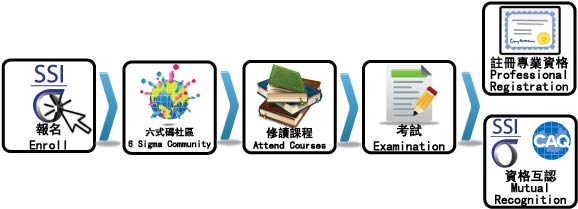

Certification and Professional Registration

Certificate of Green Belt in Six Sigma will be awarded to participants who have 70% or above attendance, complete all assignments, submit one individual project and pass the examination.

Certification holders are eligible to be registered with SSI as a Registered Six Sigma Green Belt and granted with the title of RSSGB.

Course Fee

The course fee includes:

- Examination Fee &

- Administrative Charge for issuance of “Passing Certificate” (No Hidden Cost).

Please contact us about the course fee and DISCOUNT details.

Six Sigma Green Belt Time Table

Six Sigma Green Belt

Last update: 8/7/2025 16:30

| Early-bird Deadline | Course Code | Date | Type | Time | Exam |

|---|---|---|---|---|---|

| 9 JUL | SSGB-25JUL26P | JUL 26 AUG 2, 9, 16, 23 | Saturday | 12:30pm – 6:30pm | 5 OCT |

| 16 JUL | SSGB-25AUG10P(E) | AUG 10, 17, 24, 31 SEP 7 | Sunday | 1:30pm – 7:30pm | 5 OCT |

| 4 AUG | SSGB-25SEP01On | SEP 1, 4, 8, 11, 15, 18, 22, 25, 29 OCT 2 | Online | 7:00pm – 10:00pm | 2 NOV |

Confirmed. There is a great chance that the class will be held | |||||

Six Sigma Green Belt Entry Requirements :

Applicant must have completion of F.5 or above with basic statistics knowledge (e.g. Mode, Median, Mean and Normal Curve)and preferably with 2-3 years of working experience.

If you cannot view below enrollment form, please click the DIRECT LINK HERE or DOWNLOAD the application form and send the completed form to us via email ([email protected]) or fax (25812776).