Course Pamphlet | Schedule | Enrollment | Registration

Contents

Lean Management – Adapting an Innovative Approach

Lean Leader Certification Programme

What is Six Sigma? What is Lean? What is the relationship between them?

Introduction

Lean is now considered the most effective business improvement strategy in the world, for both manufacture and service industries. Lean’s good practices to improve rapid response and eliminate waste are essential tools for re-industrialisation and in particular during the journey heading to Industry 4.0.

The innovative approach is to add, on top of improving efficiency, to enhance effectiveness of the organisations by exploiting hidden capacities. The new lean approach integrates the concept of Theory of Constraints (TOC) and focuses on creating value while reducing costs. TOC focuses on system constraints for throughput improvement.

Objectives?

The approach has received 2015年全国精益管理一等奖. Using the innovative approach of Lean will help Hong Kong enterprises to manage their organization in a much effective way during their journey towards Industry 4.0

The Workshop Provides:

1. An initial analysis, with our software, to formulate improvement directions for the participants’ companies.

2. Your executives with an integrated Lean toolkit,knowledge and application.

3. An option of providing the guidance necessary for a successful implementation of the new Lean approach

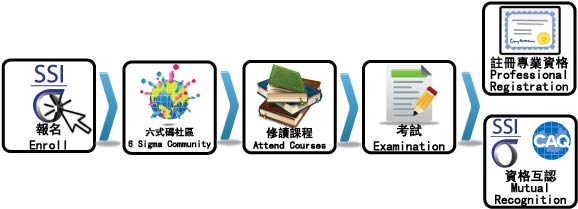

Certification and Professional Registration

Certificate of Lean Leader will be awarded to participants who have 70% or above attendance, complete all assignments, one individual project and pass the examination.

Certification holders are eligible to be registered with SSI as a Registered Lean Leader and granted with the title of RLL.

Course Fee

The course fee includes:

1. Examination Fee &

2. Administrative Charge for issuance of “Passing Certificate” (No Hidden Cost).

Please contact us about course fee and DISCOUNT details.