Course Pamphlet | Schedule | Enrollment | Registration

Contents

- 1 Certified Lean Specialist Programme

- 2 Mastering Lean Plan and Implementation

- 2.1 Introduction

- 2.2 Participants who have completed this program are able to:

- 2.3 Who should attend?

- 2.4 Course Content

- 2.5 Course Leader

- 2.6 Certification and Professional Registration

- 2.7 Course Fee

- 2.8 Course Outline

- 2.8.1 Module 1: Advanced Certificate in Strategic Lean Management(6.5-hour)

- 2.8.2 Module 2: Advanced Certificate in Lean Transformation(9-hour)

- 2.8.3 Module 3: Advanced Certificate in Flow Management and Kanban System(6.5-hour)

- 2.8.4 Module 4: Advanced Certificate in Elimination and Capacity Exploitation(6.5-hour)

- 2.8.5 Module 5: Advanced Certificate in Leveling Techniques and Balance Flow Scheduling(6.5-hour)

- 2.8.6 Module 6: Advanced Certificate in Operations Improvement Techniques(6.5-hour)

- 2.8.7 Examination

- 2.8.8 VIVA Exam

Certified Lean Specialist Programme

Mastering Lean Plan and Implementation

What is Six Sigma? What is Lean? What is the relationship between them?

Introduction

This is one of 6 modules in the Certified Lean Specialist Course. The course aims to develop senior executives with the latest knowledge and knowhows of Lean management. Upon completion of all 6 modules, the lean Specialists should have an in-depth understanding of Lean techniques that can lead and train team members to carry out Lean transformation in their organizations. They should have the competency to deliver immediate and significant business results in their business operation.

Each individual module of the Lean Specialist course is self-contained. Participants can commence the course at any module. Participants who interested to particular skill can join a particular module. A Module Certificate will be granted upon their successful completion of the module and meet the module requirements.

Participants who have completed this program are able to:

- Have a comprehensive understanding of concepts and tools of Lean Management.

- Learn from the real world (from the study visit), how these concepts and techniques are being implemented in companies.

- Apply Lean management strategically in their organizations and across the supply chain from suppliers to customers.

- Be a Lean team leadership and assign team member roles and responsibilities.

Who should attend?

- Senior managers or executives who wish to or responsible to implement Lean management in the company.

- High flyers who want to have a better opportunity in their carrier path.

- Professionals who responsible for business process improvement.

Course Content

| Module 1: | Advanced Certificate in Strategic Lean Management | 6.5-hour |

| Module 2: | Advanced Certificate in Lean Transformation | 9-hour |

| Module 3: | Advanced Certificate in Flow Management and Kanban System | 6.5-hour |

| Module 4: | Advanced Certificate in Wastes Elimination and Capacity Exploitation | 6.5-hour |

| Module 5: | Advanced Certificate in Leveling Techniques and Balance Flow Scheduling | 6.5-hour |

| Module 6: | Advanced Certificate in Operations Improvement Techniques | 6.5-hour |

| Module 7: | Lean Study Visit | Optional |

| Examination | Participants should attend the examination after completing Module 1- 6 | 2-hour |

| VIVA Exam | 30-minute individual project presentation + 30-minute Q & A session | 1-hour |

Course Leader

Dr. YK Chan, Doctor of Engineering (Warwick), Doctor of Management (IMC/USC), Registered Professional Engineer, Registered Six Sigma Master Black Belt, Certified Six Sigma Black Belt Teacher, Registered Lean Specialist, Certified Theory of Constraints Supply Chain and Logistic Application Practitioner (including production process). 30 years of experience in both manufacturing and servicing industries. Led 47 Lean Sigma projects and trained over 1,500 Lean Six Sigma professionals. Dr. Chan is a Visiting Professor of Beijing Normal University (北京師範大學) an Industrial Fellow of Warwick University

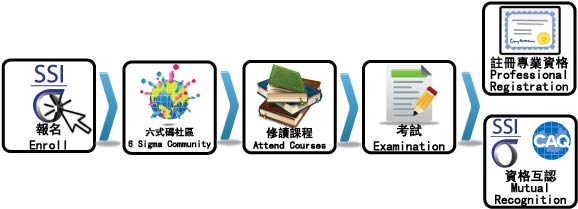

Certification and Professional Registration

Participants who complete each module with attendance 70% or above will receive a module certificate.

Registration Certificate of Lean Specialist will be awarded to participants who complete an individual project and pass the written examination. The individual project is required to be presented in the VIVA exam which includes a 30-minute project presentation and a 30-minute Q & A session.

Course Fee

The course fee includes:

1. Multiple Choice Examination Fee &

2. Administrative Charge for issuance of “Completion Certificate” for each module (No Hidden Cost).

Please contact us about course fee and DISCOUNT details.

Adverse Weather Class Arrangement

Course Outline

Module 1: Advanced Certificate in Strategic Lean Management

(6.5-hour)

1.1 Lean Vision

1.2 Identify Improvement Opportunities

1.3 The Latest Strategy of Lean Improvement

1.4 Case Study

1.5 Why Lean + TOC

1.6 Case Example

1.7 Strategies to World-class Organization

1.8 Comparison of Different Approaches

1.9 Video Show

1.10 Managerial Decision Making for Lean Leaders

Module 2: Advanced Certificate in Lean Transformation

(9-hour)

2.1 Introduction

2.2 Lean Transformation Process

2.3 Value Stream maps

2.4 Case Study

2.5 Evaluate the current situation

2.6 Identify areas of opportunity

2.7 Modify the existing process

2.8 Implement new Standard Work

2.9 Case Examples

2.10 Video Show

Module 3: Advanced Certificate in Flow Management and Kanban System

(6.5-hour)

3.1 Concept of Flow Management

3.2 Ground Work and Preparation

3.3 One-piece Flow

3.4 Make Equipment Compact

3.5 Create U-shaped Manufacturing Cells

3.6 Video Show

3.7 Multi-process Operations

3.8 Training Multi-Process Workers

3.9 Synchronization

3.10 Case Study An Automotive Electrical Parts Factory

3.11 The Kanban System

3.12 Balance the Flow VS Balance the Load

Module 4: Advanced Certificate in Elimination and Capacity Exploitation

(6.5-hour)

4.1 Why Wastes Occur?

4.2 7 Types of Wastes

4.3 How to Identify Wastes

4.4 How to Eliminate Wastes

4.5 Secrets for Not to Creating Wastes

4.6 Case Examples

4.7 5S’s and Its Deployment

4.8 Capacity Exploitation

4.9 Increase Capacity by Reducing Variations

4.10 Increase Profit by Rationalize Product Portfolio

Module 5: Advanced Certificate in Leveling Techniques and Balance Flow Scheduling

(6.5-hour)

5.1 What is Level Production or Level Service

5.2 Lean Scheduling

5.3 Leveling Techniques

5.4 Balanced Flow Scheduling

5.5 Procedures for Changeover Improvement

5.6 Video Show

5.7 The Poke-Yoke System

5.8 Video Show

5.9 The Audit List

5.10 Examples

Module 6: Advanced Certificate in Operations Improvement Techniques

(6.5-hour)

6.1 Overview of Standard Operations

6.2 How to Establish Standard Operations

6.3 Case Study

6.4 How to Improve Operations

6.5 Steps toward Jidoka

6.6 Total Productive Maintenance, TPM

6.7 Strategies for Zero Injury and Zero Accidents

6.8 Examples

6.9 A New Way for Production Management – Managing Time Buffer

6.10 A Case Study of Transfer Batch

Module 7: Lean Study Visit

- Optional, all detail to be advised

Examination

- Participants should attend the examination after completed Module 1- 6

VIVA Exam

- 30-minute individual project presentation + 30-minute Q & A session

[/bg_collapse]