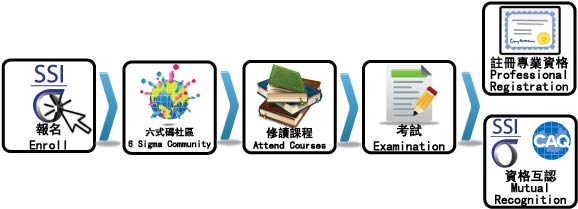

Six Sigma Institute is the only Examination Centre and authorized training centre for Certified 六式碼黑帶 of the China Association for Quality in Hong Kong.

什麼是六式碼? 什麽是精益? 他們倆個有何關係?

簡介

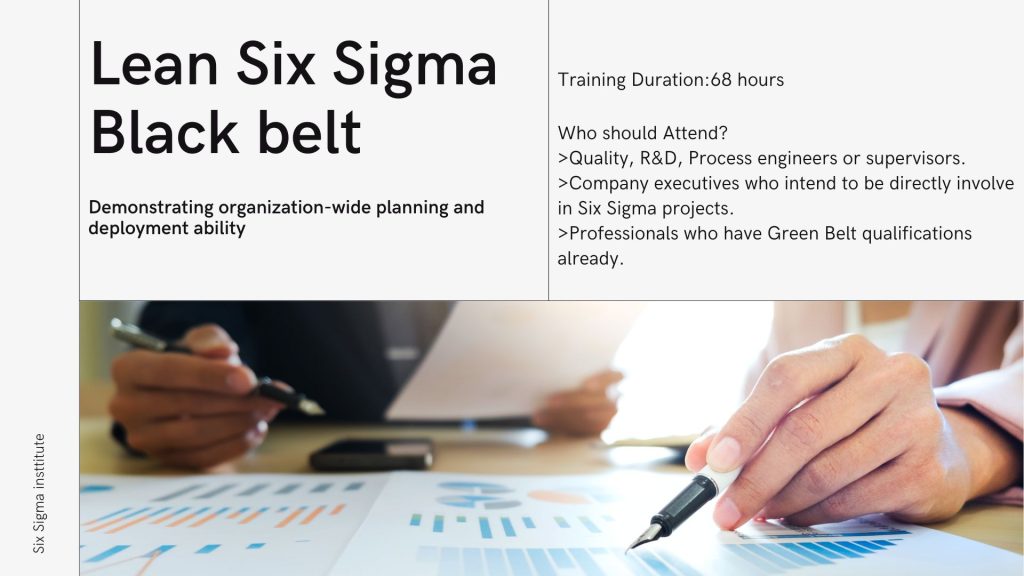

Lean Six Sigma Black Belts are the core of Lean Six Sigma Scheme in Six Sigma organisations. They have developed a synergistic proficiency between technical discipline and the Six Sigma strategies, tactics, and tools. These individuals will continually work towards institutionalising the effective use of these tools throughout the corporation, its customers, and its suppliers. They also bear the responsibility of leading and driving projects with high business impact.

This course provides a comprehensive covered of Lean and Six Sigma techniques that enable the participant to grasp the essential skills to lead Lean Six Sigma projects in their organisations. Through the coaching and in-class exercises, the participants receive practical experience from Six Sigma practitioners who hold the participants hand-in-hand to identify and implement the projects in the participants’ organisations.

The Six Sigma Black Belt Certification Programme, conducted by Six Sigma Master Black Belts, contains afternoon seminars/ workshops. The participant is required to complete at least one project with the close supervision of the Six Sigma Master Black Belt within nine months after the successful passing of the Black Belt academic examination.

誰適合參加?

- 質量, R&D, Process engineers or supervisors.

- Company executives who intend to be directly involve in Six Sigma projects.

- Professionals who have Green Belt qualifications already.

證書及資格認證

Certificate of Black Belt in Six Sigma will be awarded to participants who have 70% or above attendance, complete all assignments, one group project and pass the examination.

Certificate holders who complete at least one project with verified saving of HK$500,000 or an individual simulated project in SSI’s Six Sigma Project Course are eligible to be registered with the SSI as a Registered Six Sigma Black Belt or Registered Lean Sigma Black Belt and use the title of RSSBB or RLSBB after their names.

課程費用

The course fee includes:

1. 考試費 &

2. Administrative Charge for issuance of “Passing Certificate”

請聯絡我們 關於課程費用及折扣.

課程大綱

檢視 (View)- 簡介及項目定義

0.0 Course Introduction

1.1 The latest Development of Lean, Six Sigma and Theory of Constraints (精益六式碼制約理論整合)

1.2 A Case Example of Six Sigma Projects

1.3 Contribution of TOCLSS towards Industry 4.0

1.4 Identification of Six Sigma Projects

1.5 項目約章

1.6 project schedule

1.7 High Level process Map – SIPOC

1.8 VOC, CCR and CTQ

1.9 In-class Project – Define phase

- 過程測量

2.0 Measure Phase Overview

2.1 Detail Process Map

2.2 In/Out Put Analysis

2.3 C&E Matrix

2.4 失效模式與影響分析(FMEA)

2.5 數據收集計劃

2.6 Measurement Systems Analysis

2.7 Attribute GR&R

2.8 Introduction to SigmaXL

2.9 Basic Statistics

2.10 Current Process Capability

2.11 PPM, DPMO and Sigma Level

2.12 In-class Project – Measure phase

- Analysis – Process Analysis

3.1 Overview of Analyze Phase

3.2 過程分析

3.3 Lean and Lean Transformation

3.4 Evaluate the current situation – VSM

3.5 案例研習- Manufacture

3.6 案例研習- 服務業

3.7 辨認改善機會

3.8 Law of Variations

3.9 制約理論

3.10 Wastes Elimination

3.11 Modify the Existing Process -VSM

3.12 Case Study – Manufacture

3.13 案例研習 – 服務業

3.14 Substantiate and enumerate improvements

3.15 Implement New Standard Work

- Analyze – Data Analysis

3.16 Graphical Data Analysis

3.17 Root Cause Analysis

3.18 Why-Because Tree

3.19 Validate Root Causes by Data

3.20 Graphical Tools

3.21 Confirming Causal and Effects

3.22 迴歸分析

3.23 Chi Square Tests

3.24 練習

3.25 Hypothesis Testing of Means

3.26 Testing Of Variation

3.27 Testing Of Proportion

3.28 Normality and Non-normal Data Transformation

3.29 Determine Sample Size for Tests

3.30 Two-way ANOVA

3.31 Nonparametric Tests

3.32 In-class Project – Analyze Phase

- 過程改善

4.1 Overview of Improve Phase

4.2 Introduction to Design of Experiment

4.3 DOE – One Factor at a Time

4.4 DOE – Full Factorial Design

4.5 DOE Case study

4.6 DOE Exercise

4.7 Sample Size, Centerpoint and Blocking

4.8 In-class Project – Factorial Design

4.9 Response Surface Method

4.10 RSM Case Study

4.11 In-class Project RSM Design

4.10 Lack of Fit Issues

4.11 案例研習

4.12 Fractional Factorial Design

4.13 Case Studies

4.14 In-class Project – Improve Phase

- 過程控制

5.1 Oversew of Control Phase

5.2 Risk Identification and Management

5.3 控制計劃

5.4 SPC – Continuous Control Chart

5.5 SPC – Attribute Control Charts

5.6 Cusum Chart

5.7 In-class Project Control Phase

5.8 Performance comparison

5.9 Project Review

5.10 Close the project and handover

5.11 Prospects of BB in HK, UK, Canada, Singapore, New Zealand and China

5.12 Opportunities for Further Growth

- Case Example Book – 5 BB Projects

- Presentation of In-class BB Project

- 模擬考試

- 總結 – 調查