Course Pamphlet | Schedule | Enrollment | Professional Registration

Master Black Belt Certification Programme

Contents

Become a Competent Person to Turn Challenges into Profit

Introduction

Six Sigma, Lean and TOC (Theory of Constraints) are well recognized over the world as effective methodologies for rapid financial results. The SSI’s MBB course covers a comprehensive knowledge of these methodologies and aims to develop Master Black Belts (MBBs) who are competent to employ these tools and able to elevate organizational performance rapidly.

A qualified MBB who is usually in a senior position of an organization should have knowledge and skills to provide advice to the senior management in achieving dramatic performance improvements and producing a demonstrable return on investment. On top of providing business improvement solutions, the MBB is also a Six Sigma leader in the organization and act as trainer and coach to Black Belts and Green Belts within the organization.

Upon completion of the MBB program, participants should have acquired:

- Six Sigma deployment and management skills for successful implementation and sustain the scheme in an organization.

- Training skills for conducting in-house Green Belt and Black Belt courses.

- Project coaching and Management skills to ensure project completion.

- Advanced lean and Six Sigma tools and capabilities useful in daily Lean and Six Sigma projects.

- Mentoring skills to achieve results, transfer knowledge more effectively.

- Ability to use SSI’s TOCLSS (Theory of Constraint + Lean + Six Sigma) (pronounce as TOP-CLASS approach for providing holistic improving strategies for rapid business results.

MBB Modules

| Module (13 days) | Duration | Exam Requirements | |

| 1.TOCLSS (Theory of Constraints + Lean + Six Sigma) | (4 day, 28 hours) | Individual Project | |

| 2.Advanced Six Sigma Tools | (4 day, 28 hours) | 2- hours written examination | |

| 3.Training for Trainers | (1 day, 7 hours) | Presentation | |

| 4.Project Coaching | (1 day, 7 hours) | Coach Report | |

| 5. Six Sigma Management Leader | (1 day, 7 hours) | Simulation Exercise | |

| 6.Design for Six Sigma | (2 day, 14 hours) | Group Project |

Course Leader

Dr. YK Chan, Chairman of Six Sigma Institute, Managing Director of SBTI-Hong Kong Ltd, Doctor of Engineering (Warwick), Doctor of Management (IMC/USC), Post Doctoral (Oxford), Registered Professional Engineer, Registered Six Sigma Master Black Belt, Certified Six Sigma Black Belt Teacher, Registered Lean Specialist, TOCICO Certified TOC Practitioner, Visiting Professor of Beijing Normal University (北京師範大學) and Industrial Fellow of University of Warwick, UK.

Dr. Chan has over 30 years of experience in both manufacturing and servicing industries. Being a pioneer of Lean Six Sigma development in Hong Kong, he has Led over 100+ Lean Sigma projects and trained over 5,000 Lean Six Sigma professionals, including Six Sigma Master Black Belts, Lean Sigma Black Belts, Six Sigma Green Belts, Lean Specialists, Lean Leaders. Lean Practitioners, as well as TOC professionals.

Entry Requirements for MBB Programme

• Candidates selected by personal interview before attending the MBB Course

• Candidates should have completed Six Sigma Black Belt Certification Programme before attending Training for Trainers and Project Coaching modules.

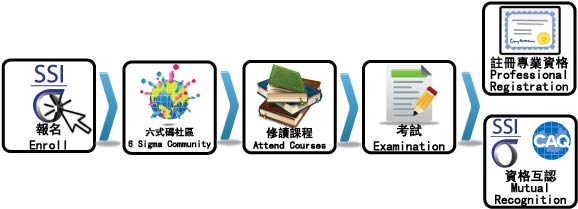

Certification and Professional Registration

Participants who have 70% attendance or above, completed all modules for the MBB programme and met all assignment and examination requirements will be awarded a Certificate of Master Black Belt in Six Sigma from SSI.

To be a Registered Six Sigma Master Black Belt, candidates must be a Registered Six Sigma Black Belt / Registered Lean Sigma Black Belt and completed all MBB modules and met all assignment and examination requirements.

Course Fee

The course fee includes:

1. Examination Fee &

2. Administrative Charge for issuance of “Completion Certificate” for each module (No Hidden Cost).

Please contact us about course fee and DISCOUNT details.

Adverse Weather Class Arrangement

Course Outline

Module #1: TOCLSS (Theory of Constraint + Lean + Six Sigma)

1.1 Overviews of the TOCLSS – A Innovative Holistic Management System

1.2 Principles and Thinking Process

1.3 Manufacturing Solutions

1.4 Performance Metrics

1.5 Project Management Solutions

1.6 Distribution, and Retail Solutions

1.7 Marketing and Sales Solutions

1.8 Strategy and Tactic

1.9 Case Examples

1.10 Individual ProjectIndividual Project Examination: Present Your Project in the Class (1 hour)

Module #2: Advanced Six Sigma Tools

2.0 Review of Hypothesis Testing and Regression Analysis

2.1 Advanced DOE2.1.1 Review of DOE Methods

2.1.2 Response Surface Design2.1.2.1 Central Composite and Box-Behnken Designs

2.1.2.2 Sequential Experimentation

2.1.2.3 Optimization

2.1.2.4 Steepest Ascent Method

2.1.2.5 Multiple Response2.1.3 Trebuchet Experiment

2.1.4 Mixture Designs2.2 Advance SPC2.2.1 Overview of SPC

2.2.2 Cusum Chart

2.2.3 EWMA Chart

2.2.4 Cumulative Count Chart

2.2.5 Multivariate Chart

2.2.6 Pre-Control Chart

2.2.7 Cases and examples2.3 Advanced Capability Analysis2.3.1 Capability Analysis for Weibull data

2.3.2 Capability Analysis for Poisson data

2.3.3 Capability Analysis for Binomial data2.4 Advance Regression Analysis2.4.1 Stepwise Method

2.4.2 Logistic Regression2.5 Forecasting Techniques2.5.1 Time Series Analysis

2.5.2 Moving Average Methods

2.5.3 Exponential Smoothing Methods

2.5.4 Autocorrelation

2.5.5 Seasonal Analysis

2.6 Simulation and Exercise

Module #3: Training for Trainers

3.1 Structure the Learning Activities

3.2 Formulation of Training plans

3.3 Effectively Creating and Controlling the Learning Environment

3.4 Teaching, Coaching and Consultancy Techniques

3.5 Practices

3.6 Individual Assignment: Teach an Assigned Subject (1 hour)

3.7 Training Examination – Presentation of your Assigned Subject

Module #4: Project Coaching

4.1 Coach-Belt Contracting as the Base

4.2 Key Questions the Coach Should Ask

4.3 Common Coaching Mistakes

4.4 The GROW Model for Coaching

4.5 Tools for the Coaching Process

4.6 Success Factors in Coaching

4.7 Practices

4.8 Individual Assignment: Coaching a Real Project

4.9 Coaching Examination – Presentation of your coaching report

Module #5: Six Sigma Management Leader

5.1 Principles of Six Sigma Management

5.2 Six Sigma Leadership and Change Management

5.3 The Role of MBB

5.4 Bringing Six Sigma to Achieve Company Objectives

5.5 Project Selection

5.6 Personnel Selection

5.7 Award and Recognition

5.8 Six Sigma Deployment Plan

5.8 Project Management and Evaluation

5.9 Aligning Six Sigma with Business Excellence Model

5.10 Aligning Six Sigma to Other Management Systems

5.11 Introduction to Six Sigma Management Standard

Module #6: Design for Six Sigma

6.1 Six Sigma Solution and Roadmap for Product Life Cycle

6.2 Introduction to DFSS

6.3 Main Technical Tools for DFSS

6.3.1 Quality Function Deployment (QFD)

6.3.2 System Design

6.3.3 Design for X

6.3.4 Applicable Reliability Engineering Tools

6.3.5 Robust Design

6.3.6 Design Validation Tools

6.4 DFSS Project Management

6.5 A Case Study of DFSS

6.6 TRIZ Inventive Problem Solving Theory

6.7 Reliability Design and Management

6.8 Workshop-Like Exercises on the Class (Conducted in the Related Parts)